Hints

We don't have any secrets at Tharwa Valley Forge and are very excited to be able to share all that we have learned about knives and bladesmithing. In addition to being the largest knife-making school in the world, we employ the largest number of full-time bladesmiths in Australia, so we've got a large base of knowledge to share with you.

Cutting a slot for a tang in thin metal can be a fiddly experience. When trying to drill a series of holes it is hard to hold down the small thin pieces of metal. Sometimes the drill bit grabs shim and it spins up damaging the it. Milling the slot has similar issues. I have been wrestling with a effective solution for years.

Cutting a slot for a tang in thin metal can be a fiddly experience. When trying to drill a series of holes it is hard to hold down the small thin pieces of metal. Sometimes the drill bit grabs shim and it spins up damaging the it. Milling the slot has similar issues. I have been wrestling with a effective solution for years.

Lately I found a 1 ton hand punch on eBay for $30 that makes quick work of the job. It is like a leather punch on steroids. It can punch different sizes holes in thin brass, spacer material or leather with little effort. It is safe and quick to use and doesn't bend the shims. It comes with seven different sized punches.

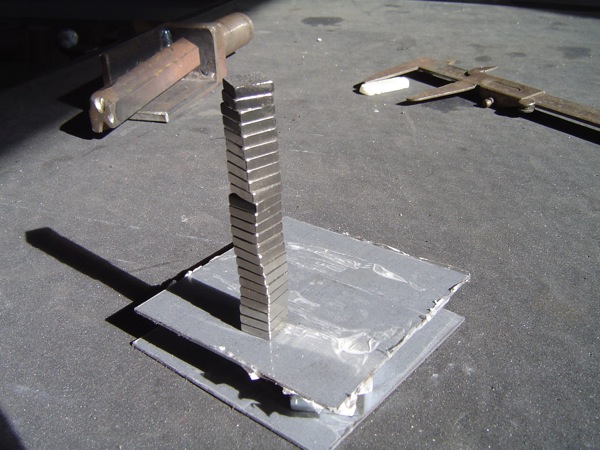

One of the challenges in forge welding is preventing the surfaces that you want to weld together from oxidising when heating. If they do oxidise, then the weld can have inclusions or gaps, which can open up later. A flux is used to stop this surface oxidation, or to dissolve it. For years I had used Borax to prevent this. When the pieces were heated, the Borax powder was sprinkled all over the surfaces, allowed to melt, then the pieces were hammered together. The problem with Borax is that it is highly corrosive when liquid, especially bad for the forge lining. Borax can easily eat through the lining in a session. To prevent this, I filled the bottom half of the forge with some sacrificial kitty litter (the clay type), which mostly caught the Borax. This didn't protect the sides though.

One of the challenges in forge welding is preventing the surfaces that you want to weld together from oxidising when heating. If they do oxidise, then the weld can have inclusions or gaps, which can open up later. A flux is used to stop this surface oxidation, or to dissolve it. For years I had used Borax to prevent this. When the pieces were heated, the Borax powder was sprinkled all over the surfaces, allowed to melt, then the pieces were hammered together. The problem with Borax is that it is highly corrosive when liquid, especially bad for the forge lining. Borax can easily eat through the lining in a session. To prevent this, I filled the bottom half of the forge with some sacrificial kitty litter (the clay type), which mostly caught the Borax. This didn't protect the sides though.

A new method of fluxing is to use Kerosene. By soaking the pieces in Kerosene before heating, you coat the surfaces in the oily liquid. When the steel is put into the forge, the Kerosene burns off, leaving a layer of carbon coating the surface, which inhibits oxidisation. The advantages is that Kerosene can get into cracks and doesn't harm the forge lining. This will not work with already oxidised surfaces, they need to be clean to start with. Borax would still needed to dissolve the scale. But using Kerosene to start with, greatly improved the success of your first welds and limits the need of Borax.

Safety note: make sure you have the Kerosene in a fireproof container, with a lid. Don't put red hot pieces of steel in the Kerosene. Although it doesnt explode, it can flare up. And the fumes aren't too good for you either,

Cut on wooden or plastic surfaces, avoid metal, granite glass or ceramic.

The blade may discolour with use, especially after contact with acidic food like tomatoes or citrus. This does not harm the blade, it can be cleaned with some fine steel wool if desired.

Clean the blade immediately after use with water, then dry it. Don't let it stay wet for too long.

Please, never put it into a dishwasher.

Clean the handle with a damp cloth. Keep the handled lightly oiled with some cooking oil.

Store them in a wooden knife block or on a wall mounted magnet. Avoid storage in drawers unless the blade is wrapped up.

Keep the blade sharp using a steel or ceramic stick. Repair the edge with a diamond or water stone.

With proper care the knife will last for many generations.

The knife is meant to be used, please enjoy it.

From Modern Blacksmithing - J.G. Holmstrom 1901

From Modern Blacksmithing - J.G. Holmstrom 1901In every profession and trade it is a common thing to hear beginners say: I know, I know. No matter what you tell them, they will always answer, I know. Such an answer is never given by an old, learned or experienced man, because, as we grow older and wiser we know that there is no such thing as knowing it all. Besides this we know that there might be a better way than the way we have learned of doing the work. It is only in few cases that we can say that this is the best way, therefore we should never say, I know: first, because no young man ever had an experience wide enough to cover the whole thing; second, it is neither sensible nor polite. Better not say anything, but simply do what you have been told to do.

Fixing handles on knives can be a challenge. This simple modification to a standard Quick-Grip makes it much easier to get nice tight glue-ups of you handle. Remove the yellow pad and cut a vertical slot 4mm in one end of the Quick-Grip. You can then put the yellow pad back on an use it as a normal grip or remove it and use it for you handles.

Fixing handles on knives can be a challenge. This simple modification to a standard Quick-Grip makes it much easier to get nice tight glue-ups of you handle. Remove the yellow pad and cut a vertical slot 4mm in one end of the Quick-Grip. You can then put the yellow pad back on an use it as a normal grip or remove it and use it for you handles.

To use glue your handle and place the blade in the slot. Gently squeeze the handle. Before final tightening check alignment of the layers, then tighten it up.

For best results make sure each layer in the handle is flat and do a dry run to check the joins before gluing.