A guide for beginners

Let’s cover the two most common questions first: Where can I get an anvil? What’s the best anvil?

For many there seems to be an aura of mystery around acquiring an anvil. We often encounter people who sound like they’ve expended a lot of effort scouring the Internet for used anvils and never thought to look for a new one. Anvils aren’t rare, you just have to buy one. Read on, we’ve got a list of where you can buy one.

As for the best anvil? Head out to your workshop and take a look at your anvil. That’s the best one - the one you’ve got. You’ll know when it’s time to upgrade your anvil when you don’t feel like asking that question again.

What's an anvil?

An anvil is a large block of hardened metal, usually forged or cast steel, with at least one very flat surface. Ideally, it has high inertia so that it pushes back against hammer strikes with as much efficiency as possible.

A good rule of thumb is that your anvil should be at least 50 times heavier that what your striking with. So if you’re using a 1kg hammer to forge blades, then you need at least a 50kg anvil.

If your anvil isn’t heavy enough you can make it heavier by making the base heavier. This could be by attaching it to a tree stump, a drum of sand with plywood on top, a block made from pieces of heavy timber, etc. Whatever it’s attached to, make sure it’s secure - you don’t want to let a falling anvil meet your toe.

Types of anvils

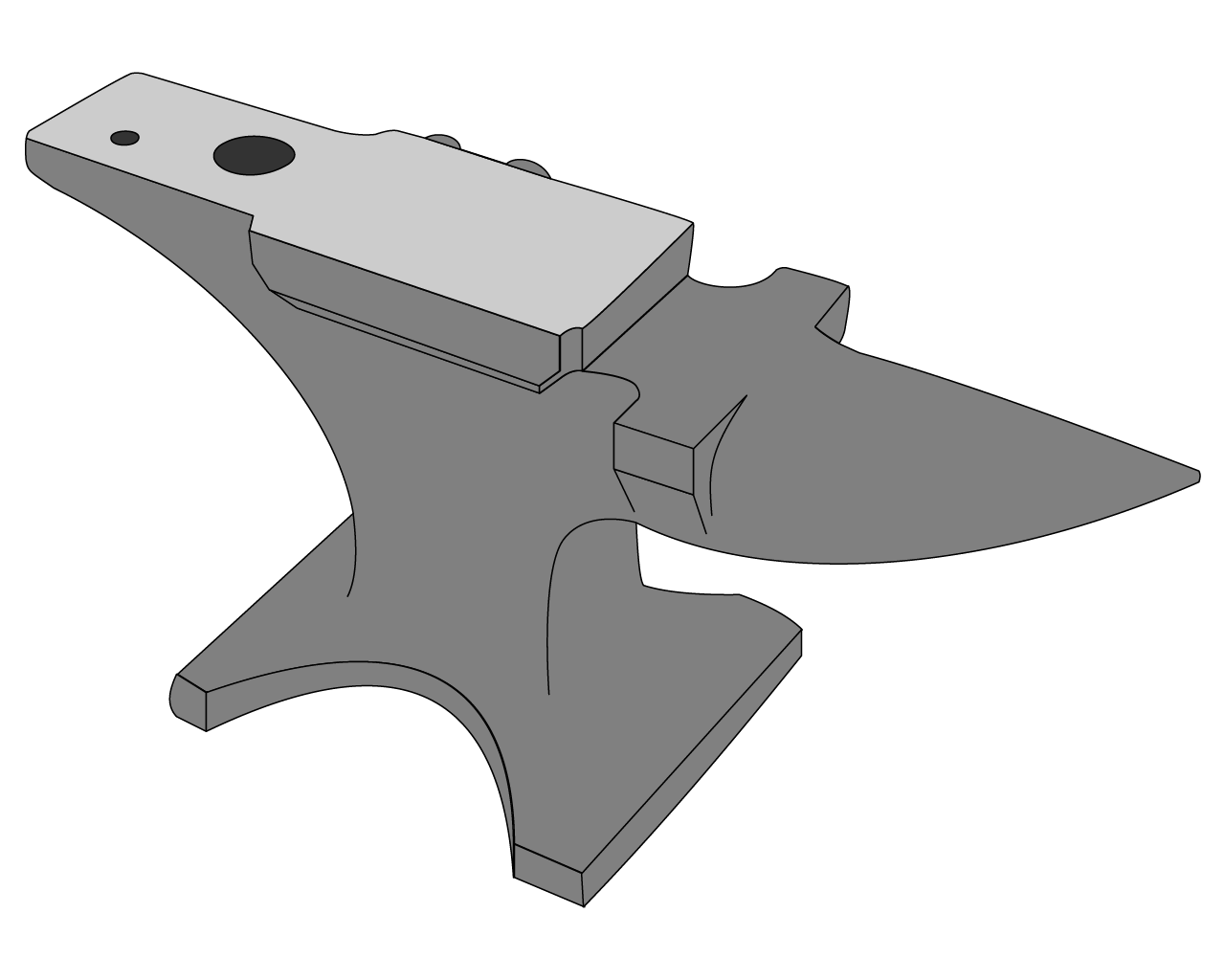

Anvils with horns

- Good for blacksmithing and bladesmithing

- Attachment points for tools (Hardie & Pritchel holes)

- Can perform a wide range of operations

Saw doctor / cutlers anvils

- Great for bladesmithing

- Bigger surface area for the weight

- Very large flat surface with good clean edges

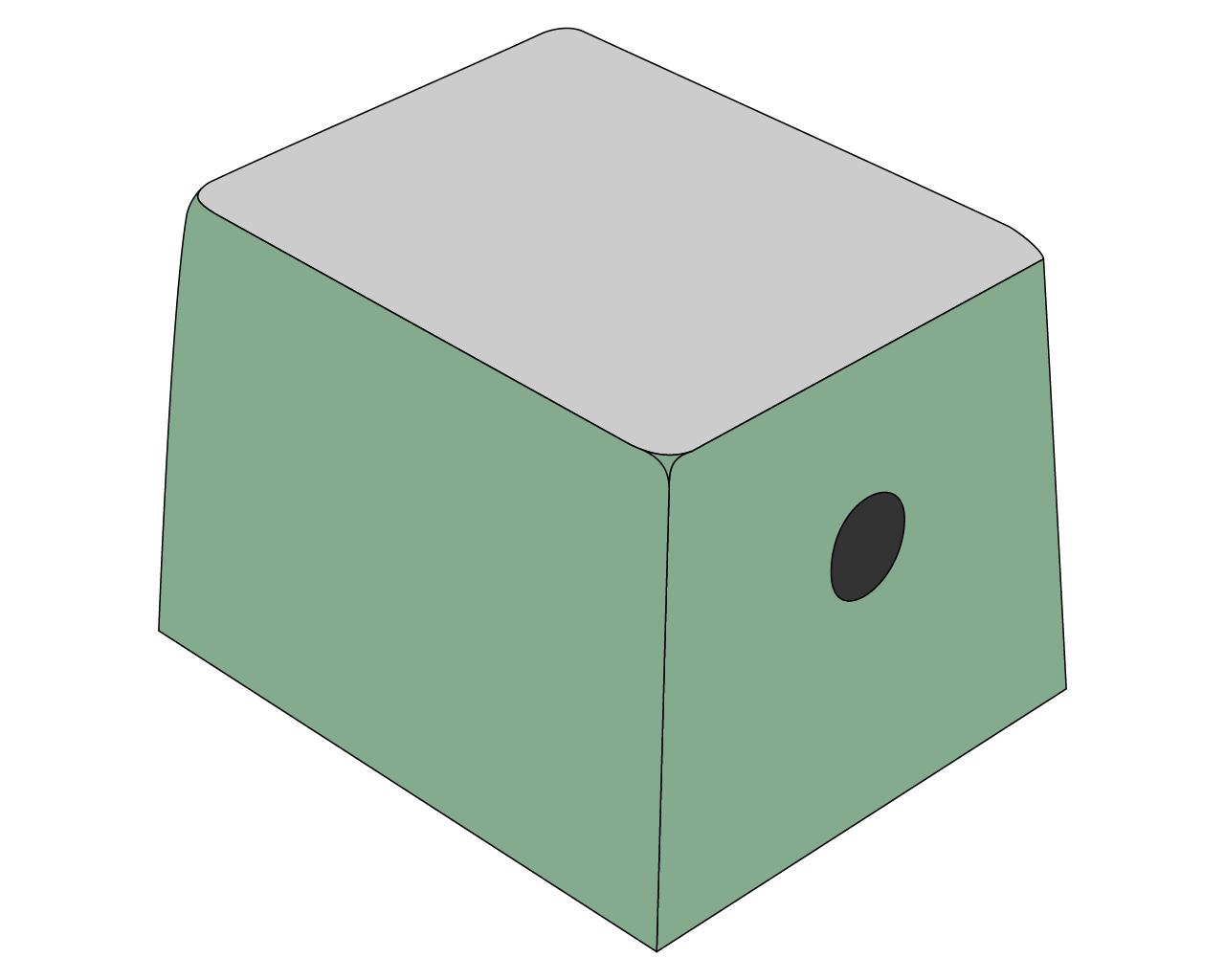

ASO (Anvil Shaped Object)

- Home-made anvils that get the job done well enough

- Typically “if it’s stupid, and it works, it’s not stupid”

- Ideally have large mass, high hardness, flat surface

- Made from a single large piece of hardened steel, Railroad rail, Forklift tines, etc

- Often use additional mass from a base of concrete, etc, to increase efficiency

Buying New

Unless you happen to stumble across a free or nearly-free anvil, we STRONGLY recommend buying a new anvil.

A new 55kg anvil can set you back around $1,000. This buys you peace of mind - you know it’s not been abused, you know it’s flat, and you don’t have to spend 20+ hours regrinding it.

Here’s some places we know and recommend. In some cases you might need to drop them an email and ask about what they can get their hands on.

Buying Used

Buying an old anvil is fraught with pitfalls, and sellers often have an overinflated view of what their anvil is worth. They often have many defects, some of which may not be apparent. That said if an anvil is looked after it should last a few lifetimes

Here’s what to look for:

- Very worn anvils indicate heavy use and likely cumulative defects

- Make sure it has a flat deck on top (check with a ruler - no light / gap / dips), any big dips are very hard to grind flat

- If an anvil started life with a horn, and now has no horn then stay away from that mistreated anvil

- Look for crisp and clean edges, missing chunks indicate abuse

- Check for hardness by using the bounce test. Drop a 15-20mm ball bearing onto the work surface from about 20cm and see how high it bounces back. This is about return - how much energy is bounced back out of the anvil. You’re looking for it to bounce back at least 75% of the distance you dropped it. The better the bounce, the less effort required to hammer and the more efficient the anvil.

- Make sure it’s got a clean Hardy and / or Pritchel hole (measure the size to make sure that it matches your tools). If these holes are chipped out it can take a lot of work to fix.

Warning

Absolutely avoid anvils made from cast iron or inferior quality steel. One mishit and you’ll have marred them to the detriment of your future work. Anvils like this are typically the cheap Chinese ones or anything sold at a hardware store.

If you’ve got any questions please feel free to send me an email.